- Home Page

- Company Profile

-

Our Products

- Roofing Sheet

- Upvc Roofing Sheet

- Galvalume Roofing Sheets

- Corrugated Steel Sheet

- Colored Roofing Sheet

- Frp Roofing Sheet

- Jsw Galvanized Roofing Sheets

- Aluminium Roofing Sheets

- Curved Roofing Sheet

- MS Roofing Sheet

- Curved Tile Profile Sheet

- Pre-coated Aluminium Roofing Sheets

- JSW Profile Roofing Sheets

- Colored Polycarbonate Sheets

- UPVC Roof Sheet

- Color Coated Aluminium Roofing Sheets

- Pre Painted Galvanized Roofing Sheets

- Tile Profile Sheet

- Bare Aluminium Roofing Sheets

- Trapezoidal Roofing Sheet

- FRP Roofing Polycarbonate Sheet

- Transparent Polycarbonate Sheet

- Polycarbonate Sheets

- Aluminium Roofing Sheet

- Hi Rib Profile Sheets

- Curved Sheet

- Crimping Roofing Sheet

- Tile Sheet

- Fibre Roofing Sheets

- Pre Coated Aluminium Roofing Sheets

- Steel Roofing Sheet

- Galvanised Roofing Sheets

- PVC White Transparent Roofing Sheets

- Pre Coated Roofing Sheets

- Tile Profile Roofing Sheet

- Essar Galvanized Roofing Sheets

- Polycarbonate Roofing Sheets

- Side Cladding Sheets

- Trapezoidal Roofing Sheets

- Crimp Curved Roofing Sheet

- GI Profile Sheet

- Stainless Steel Roofing Sheets

- Pre Painted Roofing Sheets

- Color Coated Roofing Profile Sheets

- Bare Galvalume Roofing Sheets

- Corrugated Roofing Sheets

- Color Coated Galvalume Roofing Sheets

- Metal Roofing Sheets

- Color Coated Galvanized Roofing Sheets

- Colour Coated Tile Profile Sheet

- GI Roofing Sheet

- Pre Painted Galvalume Roofing Sheets

- Insulated Roofing Panels

- Roofing Sheet Replacement

- Decking Sheet

- Pre Engineered Buildings

- Roofing System

- Air Ventilator

- Color Coated Coils

- Grating

- Roofing Screws

- Sandwich Roof Panel

- Purlins

- Polycarbonate Sheet

- Trussless Roof

- Colour Coated Sheets

- Conventional Industrial Shed

- Metal Sheet

- Prefabricated Structure

- Roofing Sheet

- Contact Us

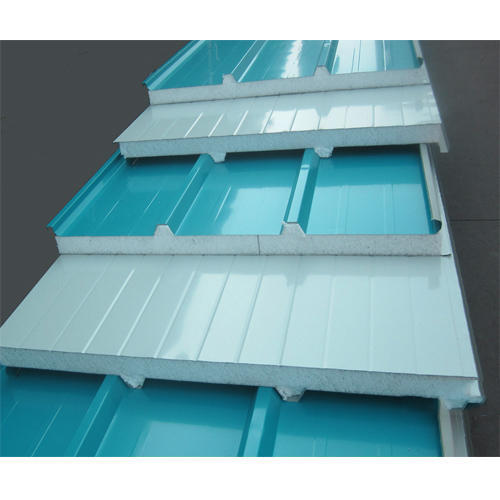

PU Sandwich Panel

1450 INR/Square Meter

Product Details:

- Usage & Applications Commercial

- Surface Treatment Coated

- Features High Thermal Insulation, Fire Resistant, Lightweight, Durable

- Material PU

- Type PU Sandwich Panel

- Size Customizable

- Shape Rectangular

- Click to view more

X

PU Sandwich Panel Price And Quantity

- 1450 INR/Square Meter

- 200 Square Meter

PU Sandwich Panel Product Specifications

- Coated

- 600 mm - 1200 mm Millimeter (mm)

- Commercial

- Customizable

- Plain / Embossed / Profiled

- PU Sandwich Panel

- Up to 12 meters (customizable) Meter (m)

- Rectangular

- High Thermal Insulation, Fire Resistant, Lightweight, Durable

- 50 - 300 mm Millimeter (mm)

- PU

PU Sandwich Panel Trade Information

- 20000 Square Meter Per Month

- 15-20 Days

Product Description

Known for their excellent insulation properties, offered PU Sandwich Panels can be availed in 0.6mm thickness and maximum 40 kg/cbm density based specifications. Thickness of their PU coating ranges between 40 mm to 150 mm. These panels are made of dual layered polyurethane materials. Usually, such panels are needed to design roof and wall of factory structure, gym, cold storage unit, exhibition hall etc. Provided PU Sandwich Panels are weather proof, have light weight and have standard dimension. We offer these insulation products at reasonable price.

Product details of PU Sandwich Panel

|

Density |

100 - 200 kg/m3 |

|

Thickness |

50 - 300 mm |

|

Width |

600 mm - 1200 mm |

|

Material |

Steel / Stainless Steel |

|

Surface Treatment |

Coated |

|

Usage/Application |

Commercial |

FAQs of PU Sandwich Panel

Q1: What are PU Sandwich Panels made of?

A1: They consist of a rigid polyurethane foam core sandwiched between two layers of galvanized steel or aluminum sheets.

Q2: What are the main applications of PU Sandwich Panels?

A2: They are commonly used in cold storage, warehouses, prefabricated buildings, industrial sheds, and roofing & wall cladding.

Q3: What are the advantages of using PU Sandwich Panels?

A3: Key benefits include high thermal insulation, lightweight design, fire resistance, soundproofing, and easy installation.

Q4: Can the thickness and size of PU Sandwich Panels be customized?

A4: Yes, the panels can be customized in thickness (30mm-200mm), length (up to 12m), and width as per project requirements.

Q5: How do PU Sandwich Panels improve energy efficiency?

A5: Their low heat transfer coefficient provides superior insulation, reducing energy consumption for cooling and heating in buildings.

Superior Thermal Insulation and Fire Resistance

PU Sandwich Panels are renowned for their remarkable thermal insulation properties, effectively minimizing energy loss in buildings. Additionally, their fire-resistant design ensures enhanced safety in commercial environments. This combination makes them an excellent choice for temperature-controlled spaces and safety-conscious projects.

Versatile Applications and Customizable Solutions

Available in a range of thicknesses, widths, and surface patterns, PU Sandwich Panels can be customized to suit diverse commercial requirements. Their lightweight, durable build permits easy installation and transportation, making them suitable for offices, warehouses, and showrooms throughout India.

FAQs of PU Sandwich Panel:

Q: How are PU Sandwich Panels installed in commercial buildings?

A: PU Sandwich Panels are installed by securing them to structural frames using mechanical fasteners or adhesives. Their lightweight nature enables quick and efficient mounting, and the panels can be cut to precise dimensions on site for seamless integration.Q: What benefits do PU Sandwich Panels offer for energy efficiency?

A: They provide high thermal insulation, which reduces energy consumption for heating and cooling in commercial spaces. This not only lowers monthly utility expenses but also contributes to sustainable building practices.Q: When should PU Sandwich Panels be considered for construction projects?

A: PU Sandwich Panels are ideal for projects requiring superior insulation, fire resistance, and durability. They are especially recommended during the initial stages of commercial building design when customization of panel dimensions and finishes is essential.Q: Where can PU Sandwich Panels be sourced in India?

A: PU Sandwich Panels are widely available through dealers, distributors, exporters, manufacturers, and suppliers throughout India. Major cities and industrial hubs typically house multiple service providers offering customizable panel solutions.Q: What is the process for customizing PU Sandwich Panels to specific project needs?

A: Clients can specify panel thickness, width, length, and surface pattern according to their requirements. Manufacturers then design and produce panels to these specifications, ensuring optimal fit and performance for each commercial application.Q: How does the durable and lightweight design enhance usage and installation?

A: The lightweight construction simplifies transportation and assembly, while the panels durability ensures long-lasting performance, reducing ongoing maintenance and replacement costs in commercial settings.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Sandwich Roof Panel' category

"We are accepting bulk order quantity from Gujarat, Maharashtra, Rajasthan and Madhya Pradesh."

Call Me Free

Call Me Free